RADFORD, VA – Thomson Industries, Inc., a leading manufacturer of mechanical motion control solutions, has created a video that details how its smart linear actuators have benefited Tribine Harvester, LLC, a recent entrant into the grain harvester market. The six-minute video explores the challenges Tribine Harvester faced and how they managed to set their design apart from conventional harvesters by using unique applications of Thomson Electrak® HD electric linear actuators.

The new Thomson video is available on the official Thomson YouTube channel

Challenge

“A couple of challenges that we faced during the design were the control of the concaves around the rotor and the opening and closing of the grain bin extension,” said Russell Secrest, Control Systems Engineer at Tribine Harvester. “The needs for the grain bin extensions became broad because we have two large doors that we had to open and close. We also have another element in the middle which is the auger that brings the grain up into the bin.”

“The concaves need to be in a certain location, and that location varies from crop to crop,” added Bryan Clearhout, Senior Mechanical Engineer at Tribine Harvester. “You need to be able to control it and know where they are, depending on your crop conditions.” said. In the video, the Tribine Harvester team also addresses the different applications they tested prior to their final selection. They initially tried using a hydraulic actuation system but quickly ruled it out due to the complexity required to achieve accurate and reliable position feedback. Traditional electromechanical actuators also were scratched as they needed additional wiring of external devices.

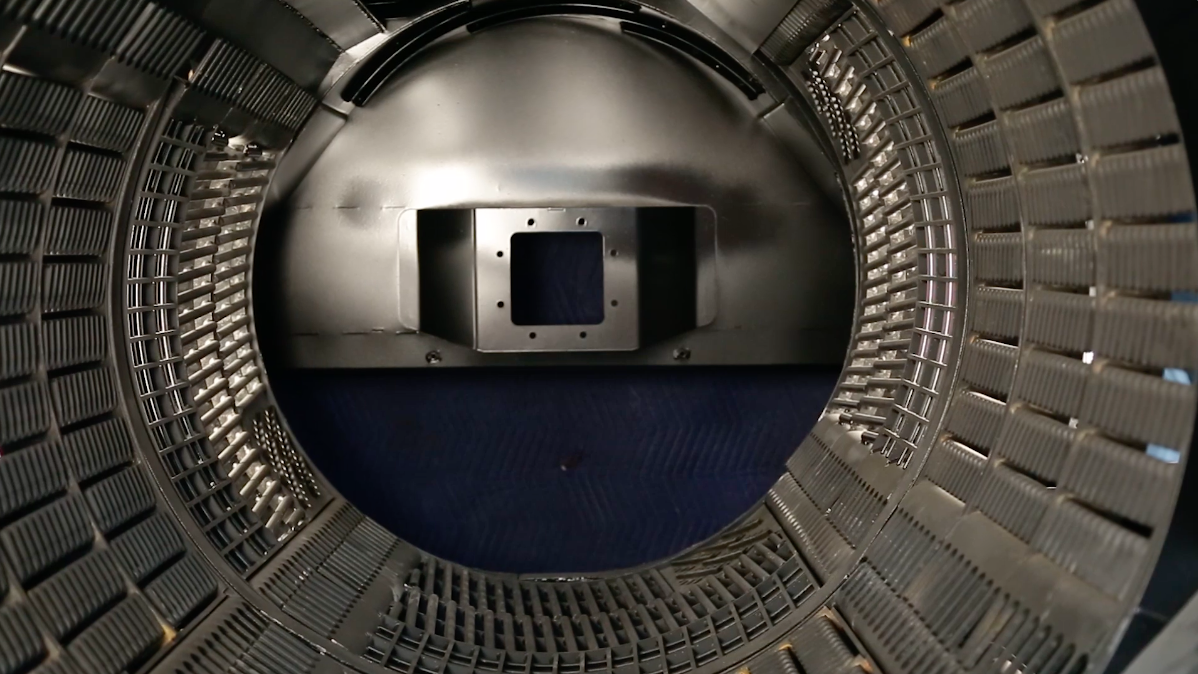

The concaves and grain bin where Thomson Electrak HD actuators are employed.

The Tribine Harvester team recognized that improving productivity would require precise control over threshing and grain bin operations, therefore, they decided to focus on using electric actuators for the concaves around the rotor and the grain bin extension.

Smart Solution and Benefits

Having consulted with experts at Thomson, Tribine Harvester resolved that the Electrak HD actuator would be suitable for their design needs and used three actuators to position the concaves and five more for the bin extension.

The Electrak HD is a smart linear actuator that carries numerous benefits. In the video, Tribine Harvester representatives highlight the following features that proved to be essential for the overall performance of their new harvester:

- Cleaner installation and easy setup and maintenance

- Dynamic braking, which improves position accuracy by preventing coasting

- Communication across a CAN bus network, offering full control and diagnostics

- Replaceable wiring harness and internal limit switches

- Analog/digital output: due to the CAN bus network, a mechanism for decoding the analog feedback on the unit is not required. With the Electrak HD, it is presented as a message to be read or driven by the controller.

A key feature of the Electrak HD actuators is that they require only two wires for CAN bus communication and two wires for power. The advantage over a traditional H-bridge is that there is no need for a separate relay or a controller that is switching power to drive the motor in either direction.

“Another feature the HD presents is that I can monitor exactly how much current it’s using and determine a fault state,” said Secrest. “Just by reading a simple CAN message, I know if one of them has failed, which I can use to not allow damage to occur to the system and be able to report that back to the operator. Whereas with the traditional H-bridge, that’s much more difficult to achieve.”

Tribine Harvester is already shipping vehicles with this advanced design, and the Thomson Electrak HD actuator is proving to have been the right choice.

To view the full video, please visit: https://www.youtube.com/watch?v=7Ncs1HBasp4.

For more information about Thomson’s range of linear actuators, please visit: http://www.thomsonlinear.com/smart.

About Thomson Industries, Inc.

With more than 70 years of motion control innovation and quality, Thomson is the industry’s premier producer of Linear Ball Bushing® Bearings and Profile Rail Bearings, 60 Case® Shafting, Ground and Rolled Ball Screws, Linear Actuators, Gearheads, Clutches, Brakes, Linear Systems and related accessories. Thomson invented the Linear Ball Bushing Bearing in 1945 and has set the standard ever since with an unsurpassed set of mechanical motion control solutions serving global commercial and aerospace and defense markets. Thomson has facilities in North America, Europe and Asia with more than 2000 distributor locations arou

Thomson Industries, Inc., 203A West Rock Road, Radford, VA 24141; 1-540-633-3549; 1-540-633-0294 (fax); [email protected]; www.thomsonlinear.com/.